Top 5 Benefits of Using Automated Manufacturing

Choose S&J for your Projects — Both Small and Large-Scale

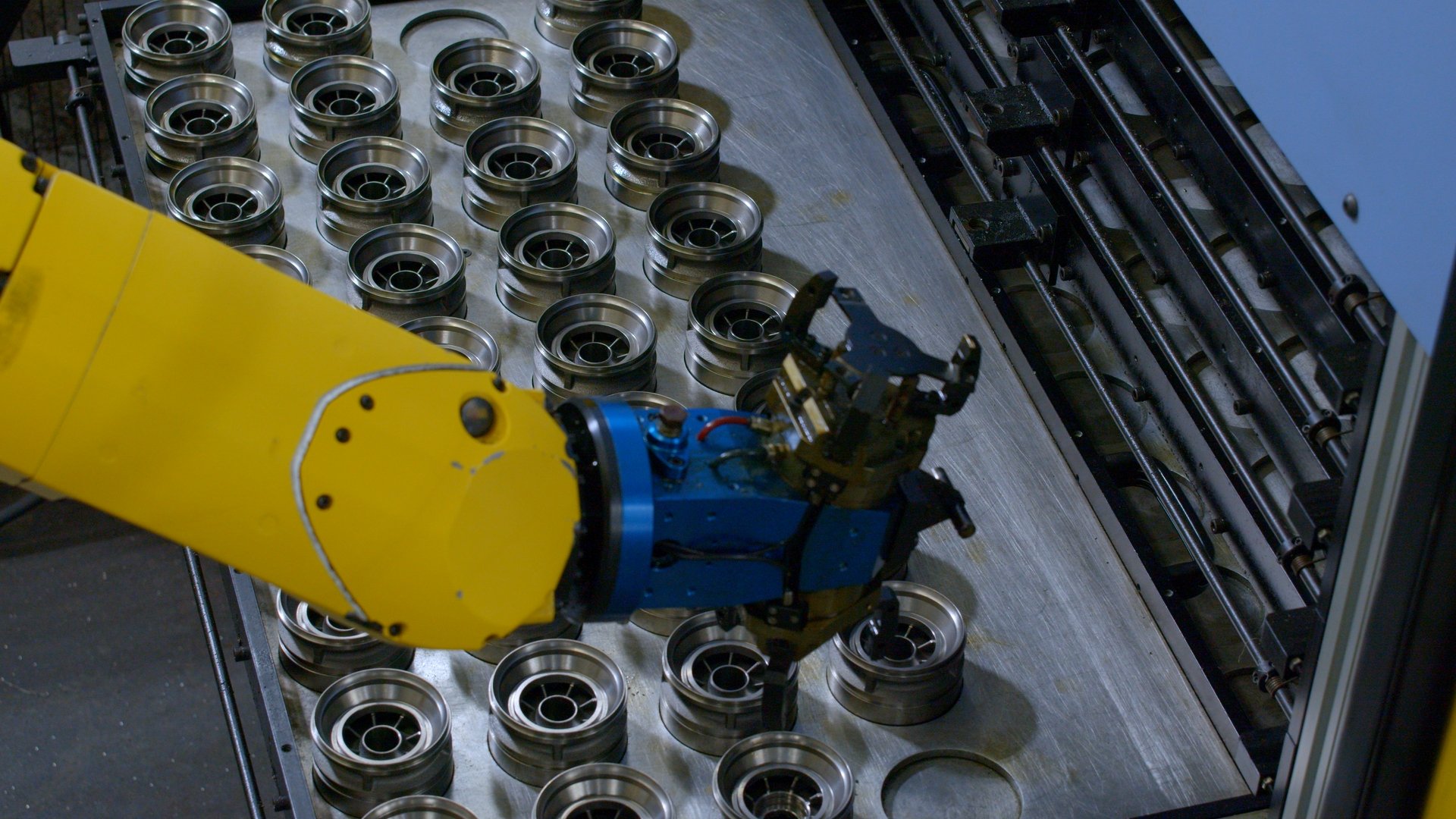

In the fast-paced world of manufacturing, meeting tight deadlines while maintaining high standards of quality is a challenge that every company faces, especially when it comes to large-scale projects. S&J Manufacturing has risen to this challenge by embracing advanced automation in their production processes. Automation not only accelerates production but also ensures precision and consistency, making it an invaluable tool for large-scale manufacturing. Here are the top five benefits of using automated manufacturing for large-scale projects, and how S&J Manufacturing leverages these advantages to meet the demands of big clients.

1. Increased Production Speed

One of the most significant benefits of automated manufacturing is the ability to drastically increase production speed. Automated machinery operates continuously, without the need for breaks, shift changes, or downtime associated with manual labor. This means that large quantities of products can be manufactured in a shorter time frame, which is critical for meeting tight deadlines.

At S&J Manufacturing, our automated systems are designed to handle large volumes of work efficiently, allowing us to complete big projects faster than traditional methods. Whether it's producing thousands of custom parts for an oil and gas operation or delivering large orders of complex components, our automation capabilities ensure that we can meet even the most aggressive timelines.

2. Enhanced Precision and Consistency

Automation takes the guesswork out of manufacturing. Automated systems are programmed with exact specifications, ensuring that each part is produced with the same high level of precision and consistency. This is especially important in large-scale projects, where even minor deviations can lead to significant issues down the line.

S&J Manufacturing’s advanced CNC (Computer Numerical Control) machines are at the heart of our automation process, delivering parts with exceptional accuracy. This consistency across large production runs not only meets the stringent quality standards of our clients but also reduces waste and rework, further streamlining the production process.

3. Cost Efficiency

While the initial investment in automation technology can be substantial, the long-term cost savings are considerable. Automated manufacturing reduces labor costs by minimizing the need for manual intervention and allowing for more efficient use of materials. Moreover, the speed and precision of automated systems reduce the likelihood of errors and defects, leading to fewer costly mistakes.

At S&J Manufacturing, we’ve found that automation enables us to offer competitive pricing on large-scale projects without compromising on quality. The efficiencies gained through automation translate into cost savings that we can pass on to our clients, making us a cost-effective choice for large-scale manufacturing needs.

4. Scalability for Large Projects

Scalability is another critical advantage of automated manufacturing. As project sizes grow, manual processes can struggle to keep up with the increased demand, leading to bottlenecks and delays. Automated systems, on the other hand, can be easily scaled to handle larger volumes by simply adjusting the machine programming or adding additional equipment to the production line.

S&J Manufacturing’s automation setup is designed with scalability in mind. Whether we’re producing a small batch of custom parts or ramping up for a large-scale production run, our automated systems can easily adjust to meet the project’s demands. This flexibility ensures that we can take on projects of any size without sacrificing efficiency or quality.

5. Improved Safety and Reduced Risk

Manufacturing environments can be hazardous, particularly when dealing with heavy machinery and large-scale operations. Automation helps to reduce these risks by minimizing the need for human intervention in dangerous tasks. Automated systems can handle repetitive, strenuous, or high-risk activities, reducing the likelihood of workplace accidents and improving overall safety.

At S&J Manufacturing, safety is a top priority. Our automated processes are designed to not only enhance efficiency but also to protect our workforce by limiting their exposure to potentially dangerous tasks. By automating high-risk operations, we reduce the risk of injury and ensure a safer working environment, which is beneficial both for our employees and for maintaining uninterrupted production.

Conclusion

In conclusion, automated manufacturing offers numerous benefits that make it an ideal solution for large-scale projects. By increasing production speed, enhancing precision, improving cost efficiency, offering scalability, and boosting safety, automation allows S&J Manufacturing to meet the demands of big clients while maintaining the highest standards of quality and reliability. As we continue to invest in cutting-edge automation technology, S&J Manufacturing remains committed to delivering exceptional results for large-scale projects, no matter how tight the deadline or how complex the requirements.